Work-in-Process (WIP) inventory is an important part of any manufacturing or production process. It refers to the materials that are in the process of being transformed into finished goods. Essentially, WIP inventory is the midway point between raw materials and finished products. If you're running a manufacturing process, it's essential to know how much WIP inventory you have at any given time. This can help you optimize your production process and reduce waste. In this post, we'll take a closer look at what WIP inventory is and how you can calculate it. So, what exactly is WIP inventory? As we mentioned earlier, it's the materials that are currently in the process of being transformed into finished goods. This includes partially completed products, raw materials, and other components that are waiting to be assembled. To calculate your WIP inventory, you'll need to take into account the value of all of the materials that are currently in the production process. This can include the cost of raw materials, labor costs, and overhead costs associated with the manufacturing process. One of the key benefits of tracking your WIP inventory is that it can help you identify bottlenecks in your production process. For example, if you have a lot of raw materials sitting in WIP inventory, it could be a sign that your production process is inefficient or that you're ordering too many materials. To optimize your production process, you'll need to take a closer look at your WIP inventory levels and identify areas where you can make improvements. This might involve streamlining your production process, improving your inventory management systems, or reevaluating your raw materials ordering process. Ultimately, if you're running a manufacturing or production process, it's essential to keep a close eye on your WIP inventory levels. By doing so, you can ensure that your production process is running smoothly and that you're not wasting valuable resources on excess inventory or inefficient processes. So, take some time to evaluate your WIP inventory today and see where you can make improvements!

What is Work in Process Inventory and How-to Calculate WIP

Work-in-Process (WIP) inventory is an important part of any manufacturing or production process. Essentially, WIP inventory is the midway point between raw materials and finished goods.

What is work-in-process inventory (WIP) | Bookstime

To calculate your WIP inventory, you'll need to take into account the value of all of the materials that are currently in the production process. This can include the cost of raw materials, labor costs, and overhead costs associated with the manufacturing process.

If you are looking for What is work-in-process inventory (WIP) | Bookstime you've visit to the right web. We have 6 Images about What is work-in-process inventory (WIP) | Bookstime like What is beginning inventory: beginning inventory formula, Work in Process (WIP) Inventory - Concept and Formula Explained and also What is work-in-process inventory (WIP) | Bookstime. Here it is:

What Is Work-in-process Inventory (WIP) | Bookstime

www.bookstime.com

www.bookstime.com How To Calculate Ending Inventory Using Absorption Costing - Online

online-accounting.net

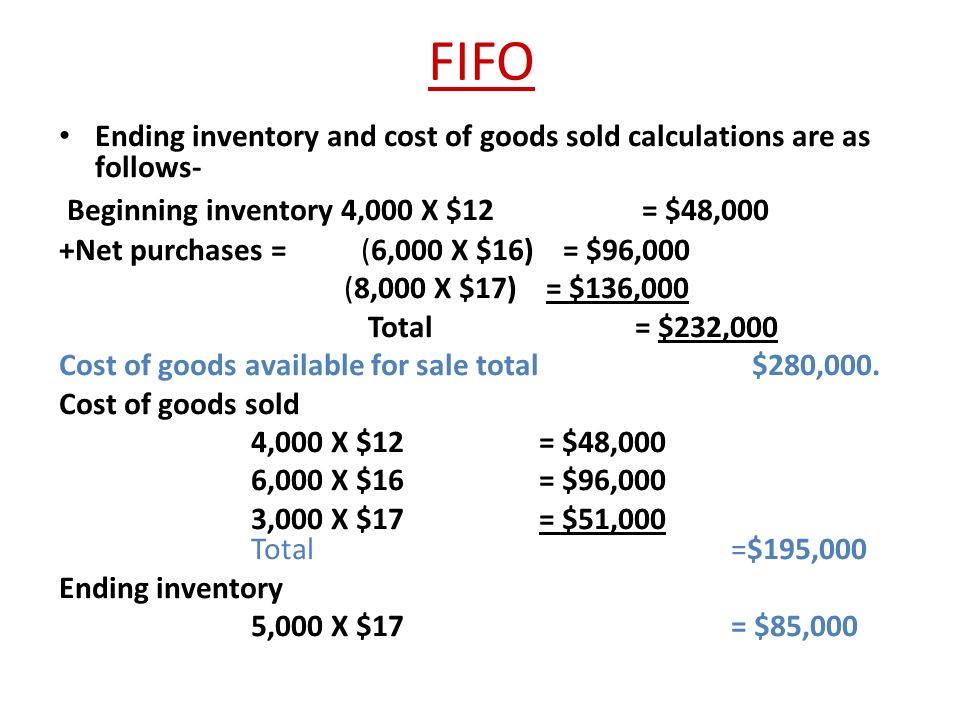

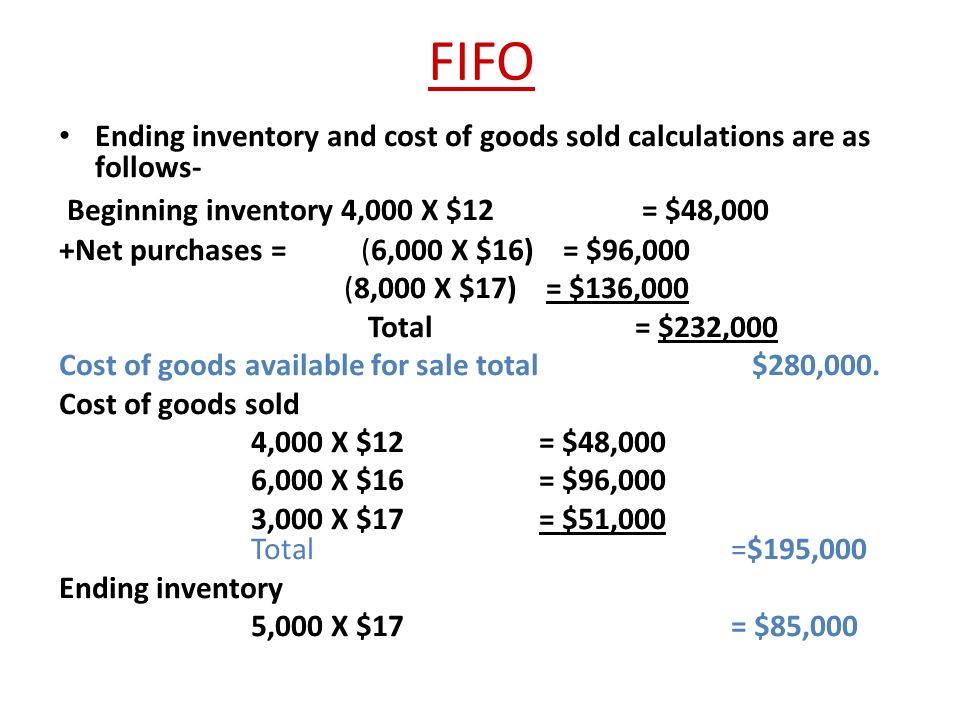

online-accounting.net calculate costing absorption fifo

Work In Process (WIP) Inventory - Concept And Formula Explained

fulfillment.shiprocket.in

fulfillment.shiprocket.in wip fulfillment shiprocket calculate

How To Calculate Beginning Work In Process Inventory - Quora

www.quora.com

www.quora.com wip calculate manufacturing inventory work beginning process costs calculated separately assembly give each being

What Is Work In Process Inventory And How-to Calculate WIP

emergeapp.net

emergeapp.net work inventory process

What Is Beginning Inventory: Beginning Inventory Formula

www.tradegecko.com

www.tradegecko.com inventory calculation purchased amount

Wip fulfillment shiprocket calculate. Inventory calculation purchased amount. Work inventory process

www.bookstime.com

www.bookstime.com  online-accounting.net

online-accounting.net  fulfillment.shiprocket.in

fulfillment.shiprocket.in  emergeapp.net

emergeapp.net  www.tradegecko.com

www.tradegecko.com

No comments:

Post a Comment